This product is not available for new orders. We recommend ordering: CR1000X.

| Services Available |

|---|

Overview

The CR10X provided sensor measurement, timekeeping, data reduction, data/program storage and control functions. The CR10X stored up to 62,000 data points. Data and programs were stored either in a nonvolatile Flash memory or RAM. A lithium battery backed up the RAM and real-time clock. The CR10X also suspended execution when primary power (BPALK, PS100) dropped below 9.6 V, reducing the possibility of inaccurate measurements.

Read MoreBenefits and Features

- Designed for unattended network applications

- Stores 62,000 data points (nonvolatile)

- Data format options are mixed array (default) or table

- Detachable keyboard/display, the CR10KD, can be carried to multiple stations

Images

Detailed Description

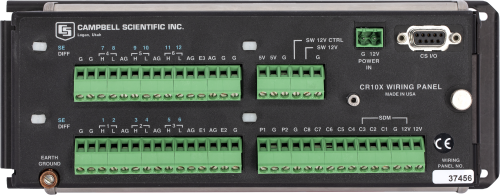

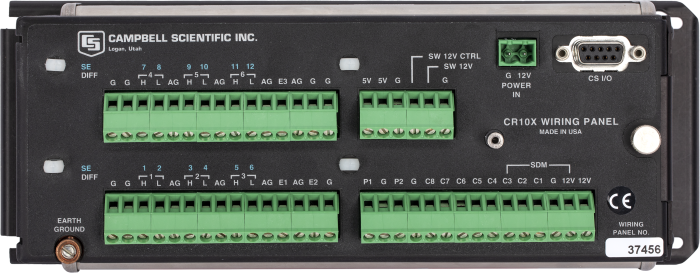

The data logger consisted of a CR10XM Measurement and Control Module and black CR10X Wiring Panel.

The CR10X provided sensor measurement, timekeeping, data reduction, data/program storage and control functions. The CR10X stored up to 62,000 data points. Data and programs were stored either in a nonvolatile Flash memory or RAM. A lithium battery backed up the RAM and real-time clock. The CR10X also suspended execution when primary power (BPALK, PS100) dropped below 9.6 V, reducing the possibility of inaccurate measurements.

Compatibility

A typical field-based CR10X system included:

- CR10X Measurement and Control Module and Wiring Panel with specified Operating System

- Alkaline or Sealed Rechargeable Power Supply

- Weatherproof Enclosure

- Communications Peripheral(s)

- Programming and Communications Software

- Sensors

Specifications

| -NOTE- | Note: Additional specifications are listed in the CR10X-Series Specifications Sheet. |

| Memory | Up to 62,000 data points |

| Analog Inputs | 12 single-ended or 6 differential (individually configured) |

| Pulse Counters | 2 |

| Switched Voltage Excitations | 3 |

| Control/Digital Ports | 8 |

| Serial I/O Port | 1 |

| Scan Rate | 64 Hz |

| Burst Mode | 750 Hz |

| Analog Volt Resolution | To 0.33 µV |

| A/D Bits | 13 |

| Programming | Edlog |

| Data Storage | Mixed Array, Table |

| Telecommunications | PakBus, Modbus, Alert |

Downloads

CR10X OS v.1.23 (1.45 MB) 02-04-2010

Execution of this download installs the CR10X Operating System (Mixed-Array) on your computer.

Note: The Device Configuration Utility is used to upload the included operating system to the datalogger. Requires an SC32A or SC32B.

CR10X-TD OS v.1.15 (645 KB) 28-03-2006

Execution of this download installs the CR10X Table Data Operating System on your computer.

Note: The Device Configuration Utility is used to upload the included operating system to the datalogger. Requires an SC32A or SC32B.

CR10X-PB OS v.1.10 (647 KB) 28-03-2006

Execution of this download installs the CR10X PakBus Operating System on your computer.

Note: The Device Configuration Utility is used to upload the included operating system to the datalogger. Requires an SC32A or SC32B.

Device Configuration Utility v.2.33 (49.6 MB) 07-07-2025

A software utility used to download operating systems and set up Campbell Scientific hardware. Also will update PakBus Graph and the Network Planner if they have been installed previously by another Campbell Scientific software package.

Supported Operating Systems:

Windows 11 or 10 (Both 32 and 64 bit)

Frequently Asked Questions

Number of FAQs related to CR10X: 1

-

A practical maximum is to connect one multiplexer per every two control terminals on the data logger. Control terminals can be shared between multiplexers to increase the number of connected multiplexers. Sharing terminals, however, requires more complex wiring and programming. Users who would like to connect more than one multiplexer per every two control terminals are advised to contact a sales or support engineer at Campbell Scientific for assistance.

Case Studies

South Africa's subtropical climate is favorable for citrus fruit production. South Africa annually exports roughly......read more

The North County Transit District (NCTD) of San Diego County, California, determined that three segments......read more

Competition for limited water resources in the western United States is increasing, as are the......read more

Forests in the Blue Ridge region are undergoing numerous changes due to: Change in land......read more

Imagine the bored mind of a space traveler as he looks around the room he......read more

Campbell Scientific recently supplied agrometeorological stations for an important research project in Costa Rica. The......read more

The Delaware Environmental Observing System (DEOS) is a real-time system dedicated to monitoring environmental conditions......read more

The Charles Sturt University (CSU) Rhizolysimeter is one of the largest root-growth research facilities in......read more